ETCS Test Environment

HW and SW platform for real time simulation and testing of onboard ERTMS-ETCS equipment

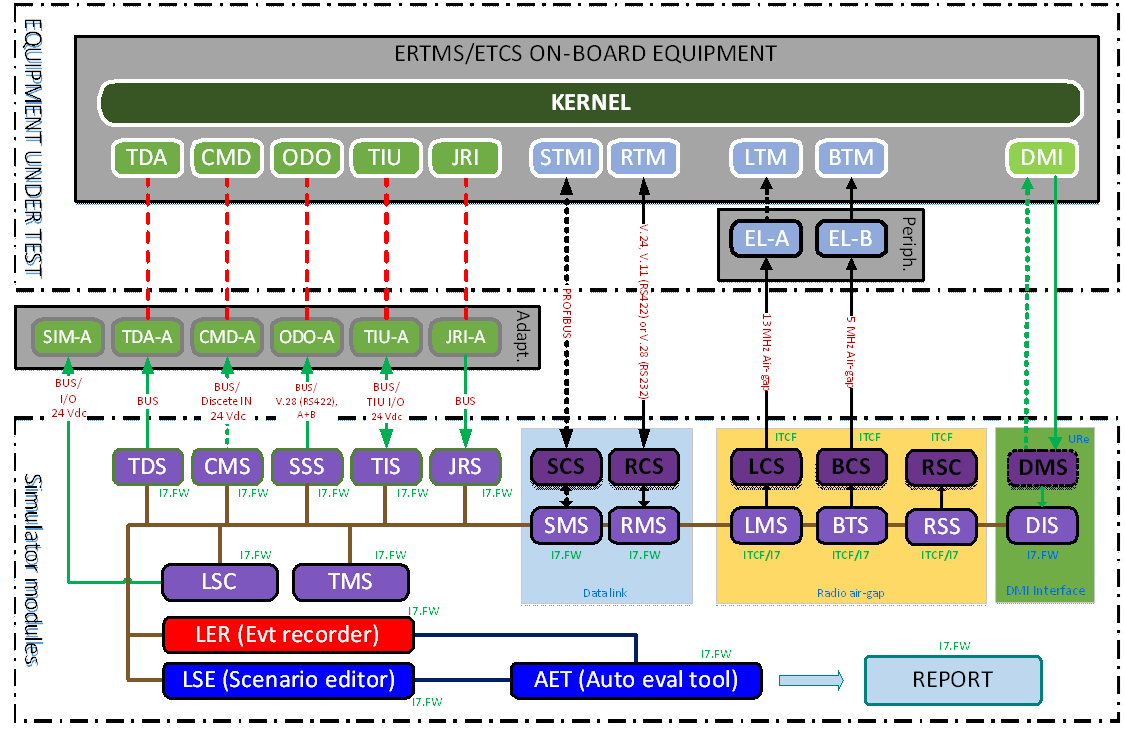

The ERTMS-ETCS test environment is compliant with the UNISIG Subset-094 architecture, to interface the ETCS onboard equipment supplied by any manufacturer.

APPLICATIONS

- Integration test with trackside devices (eurobalise, euroloop, national systems such as RSC, SCMT, etc.)

- Integration test with ERTMS trackside system (Radio Block C)

- Validation test, according with Subset-076

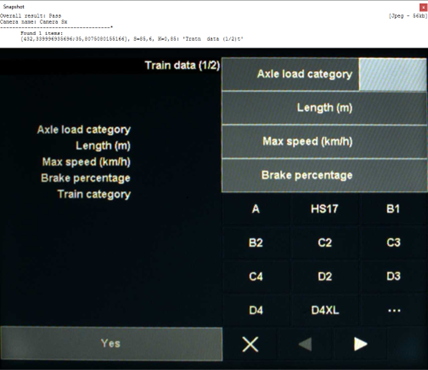

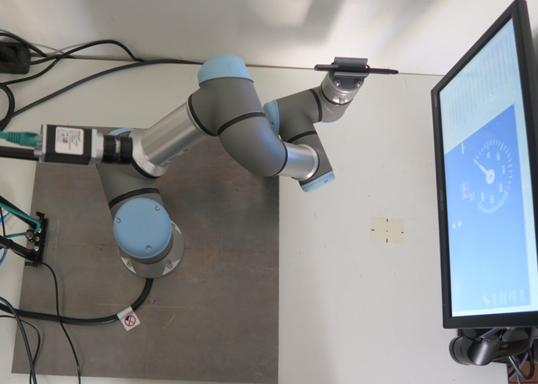

- Fully automated test, using robot/camera system to handle DMI operations

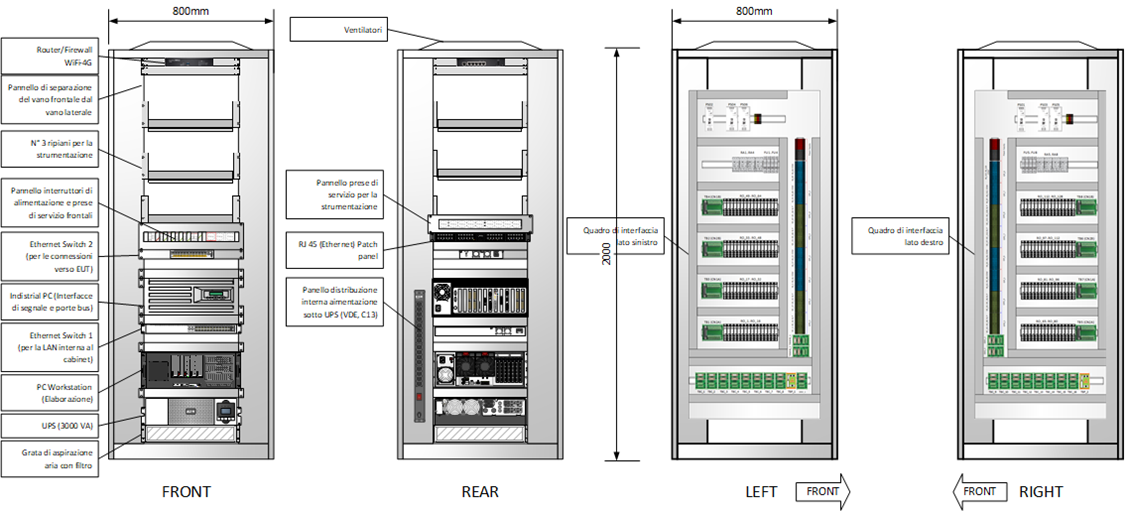

Etcs Test Architecture

Wide range of interfaces to ETCS onboard equipment

-

Full support to Subset-094 interfacing requirements:

- Wired digital I/O (24 V)

- IEEE 802.3 (Ethernet) 100/1000 Mbps, using TCP/UDP transport layers

- Async Serial port, RS232/RS422/RS485

- Digital encoder emulation (up to 500 km/h), using RS422 transmitter

- Profibus DP (FDL data link layer), to support STM communication

-

Optional Interfaces:

- MVB, for digital I/O interface to ETCS Onboard

- CAN bus

- Synchronous serial port (RS422 physical layer)

-

Euroradio Interfaces:

- GSMR modem emulation (CS mode), on RS232/RS422 serial port

-

AIRGAP Interfaces:

- Eurobalise and Euroloop emulation

- RSC emulation

-

DMI Interfaces:

- Robotic arm (Industrial standard) to emulate the driver operation on the touch screen display (or keyboard), including data entry

- High resolution GigE camera (industrial standard), to grab the DMI display images

- Recognition of symbols (icons) and text, using Matrox Imaging Libraries (MIL)

- Up two display supported

-

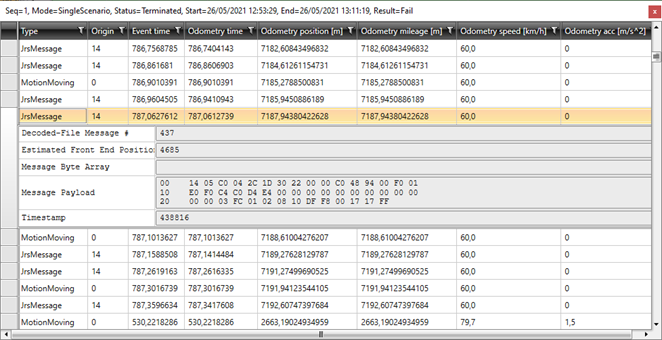

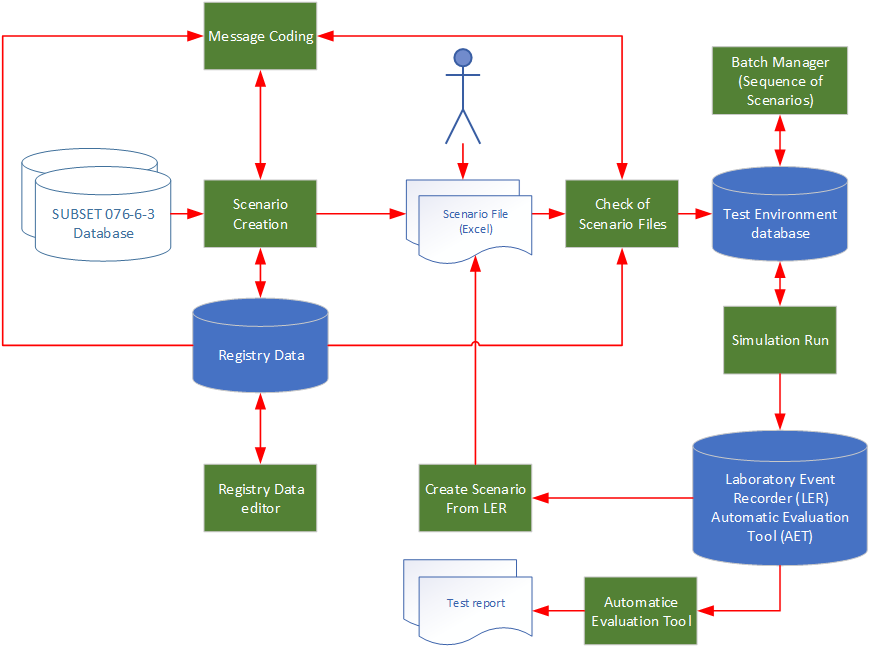

The database of Registry data contains all the information to validate the Test Sequences and the Scenario Files:

- A language has been defined for each communication protocol (BTM and LTM telegrams, STM messages, JRS messages, …) to provide automatically coding/decoding functions.

- The database supports more versions of the same Language.

- The set of used language are specified in the scenario file.

-

A specific Language has been defined to describe all the Command and Check Actions to automatically implement the test sequences:

- The command and Check Actions are used to specify the behaviour of the simulator for each step of the Test sequence

- The Actions are scheduled on position base, with the possibility to specify a time delay respect the begin or end of the previous action.

- The Check Actions are automatically evaluated at runtime

- The Test Environment database contains all the information to run the simulations

- The LER/AET database contains the simulation events and the results of each command/check actions, so the results of each step of the Test Sequence.

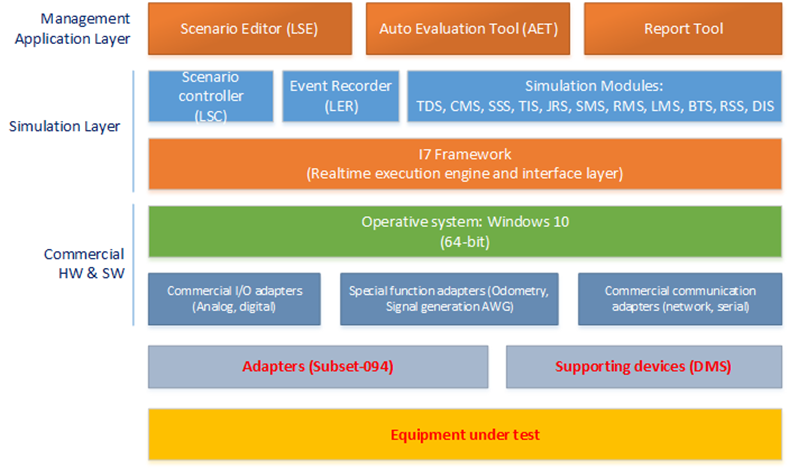

Simulation and test

- Windows based (.NET Framework) + I7 Framework real-time execution environment

- May integrate customer SW modules (SW in the loop)

-

ETCS specific modules:

- Euroradio safety layer / STM safety layer

- Eurobalise/Euroloop telegram generator

- Train Motion simulator, with hard synchronisation (0.1 m) with balise/loop transmission (up to 500 km/h)

- Flexible I/O management, via hard-wired signal or Subset-094 test protocol over TCP/UDP or serial port

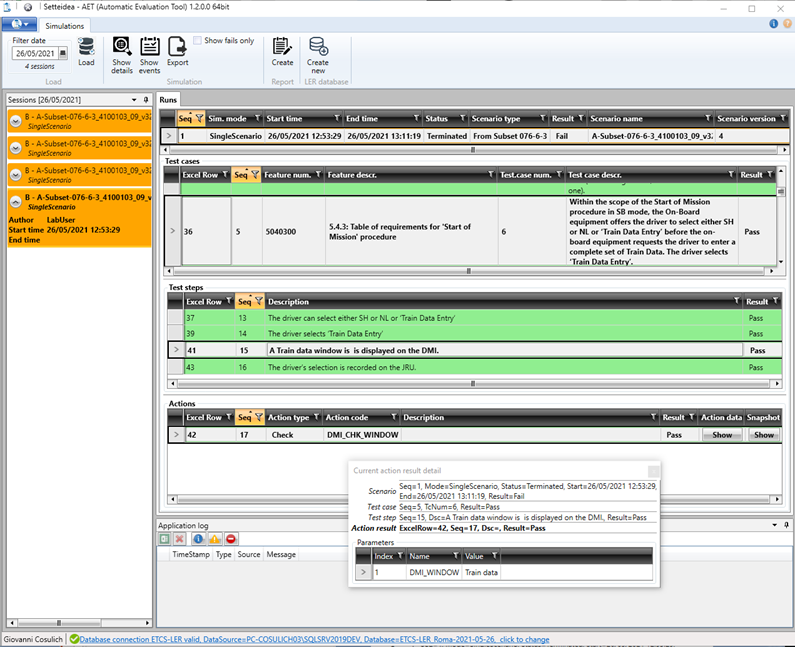

Mamanagement tools

- Windows based (.NET Framework)

-

Data storage uses MS SQL Server database for:

- Subset-076 reference source scenarios

- Custom operating scenarios

- Test result

- Protocols and languages configuration

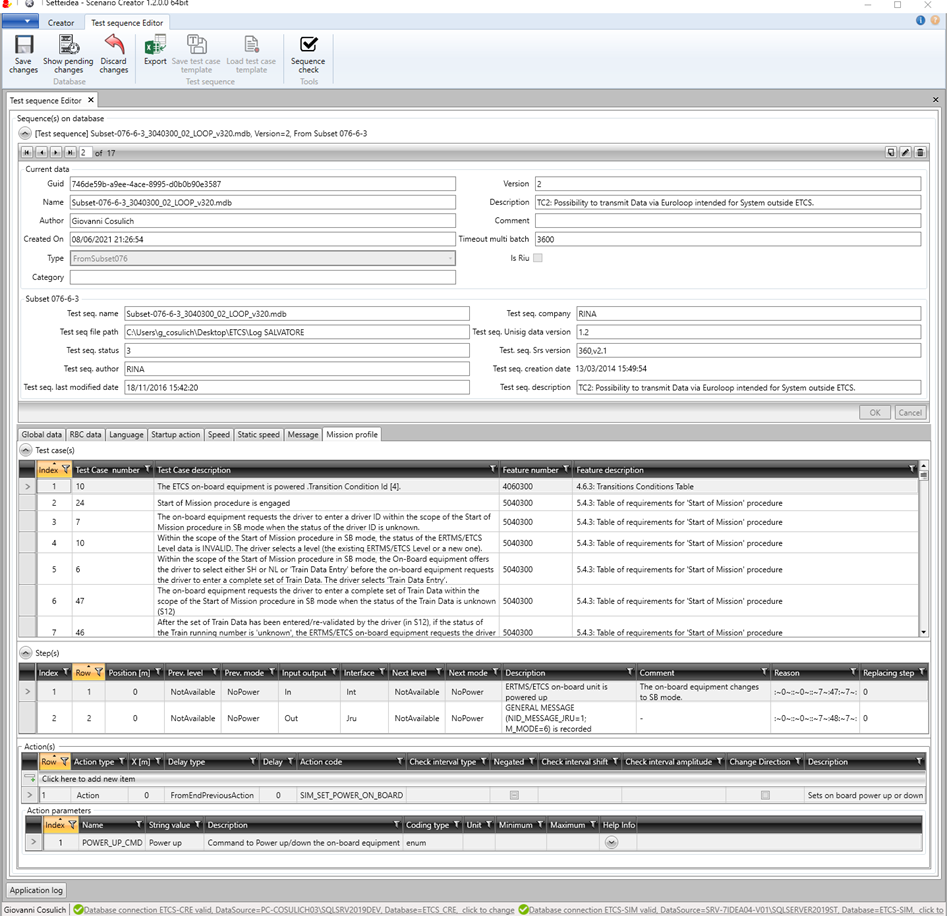

- Scenario Editor application

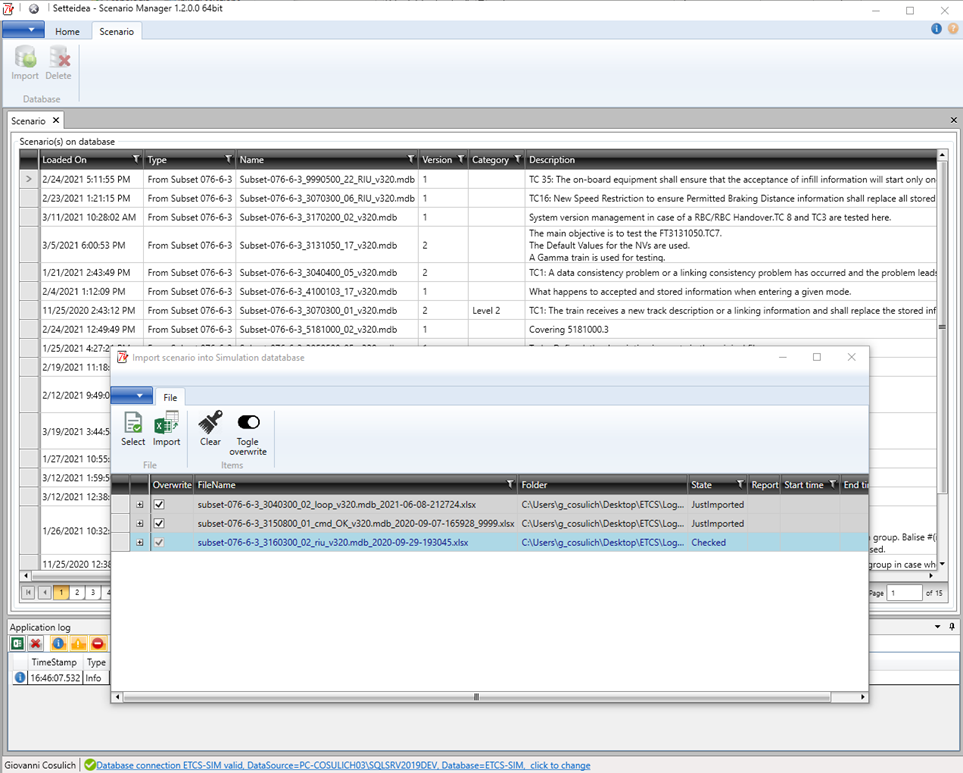

- Scenario Manager application

- Automatic Evaluation application tool, for test result analysis

- Allows to create the Scenario Files starting from the Subset 076-6-3, from the results of an interactive simulation or from an empty one

- Provides support to check and validate the Test Scenario

- Manages the data to automatically convert the Step of Subset 076-6-3 in Command and Check Actions

- Imports and Checks the Scenario Files

- Manages the data to automatically Run sequence of simulations

- Records the simulation events

- Records the results of each Command and Check Actions

- Provides Detailed Log files of the messages of all communication protocols

- Create the report (pass/fail) of the single simulation or of a sequence of simulations

- Allows to check the Simulation results at runtime